Battles over armrest space are the bane of virtually anyone who has ever flown coach on a full flight. But a seat manufacturer that just locked down its first sale aims to alleviate this perpetual source of in-flight aggravation and tension while improving the overall experience of flying in the dreaded middle seat.

Hank Scott, CEO and founder of Molon Labe Seating of Lakewood, Colo., said the company took an order a month ago to furnish seats on 20 Airbus A320s for a Chinese carrier.

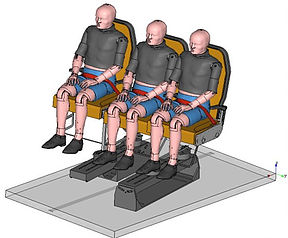

Molon Labe seats are unique in the industry because of their staggered design. For a row of three-across seats, the middle seat is set in a fixed position slightly behind and lower than aisle and window seats.

Offsetting the seats offers two advantages that Scott emphasizes during sales pitches. The first has to do with the armrest. Because the middle seat passenger is slightly behind and lower than the passengers to the right and left, their natural position to rest arms is different.

Molon Labe’s seats take advantage of this offsetting in the design of their armrests, which have an elevated front half and a lower back half — in essence creating separate spaces for each passenger to rest his or her arms.

Without a doubt, in other words, the seat offered an improvement over the slim armrests that have become the norm in economy cabins in recent years.

The second advantage that Scott emphasizes about Molon Labe’s staggered design has to do with spreaders, a component, typically made of aluminum, that connects the seat back to the seat itself. Most aircraft seats have spreaders that are positioned one next to the other, but the Molon Labe seats save space by having vertically stacked spreaders. The result is extra space in the seats themselves.

Standard Molon Labe seats in a typical six-abreast formation for a Boeing 737 are 18.4 inches, or approximately an inch wider than the industry standard. Widths can also be adjusted so that the middle seat is as wide as 19 inches while aisle and window seats have 18 inches of width.